IKOM Technical team has been committed to the deep research of sprinkler product performance, continuous innovation, is the industry's leader in technological progress. Professional construction machinery needs professional system unit design and development, so that each system can be better matched. The working principle of the sprinkler is composed of control unit and execution unit, hydraulic system of execution element and asphalt conveying system. The asphalt conveying system consists of pumps, valves and pipes. The performance of the valve has a great influence on the performance of the sprinkler.

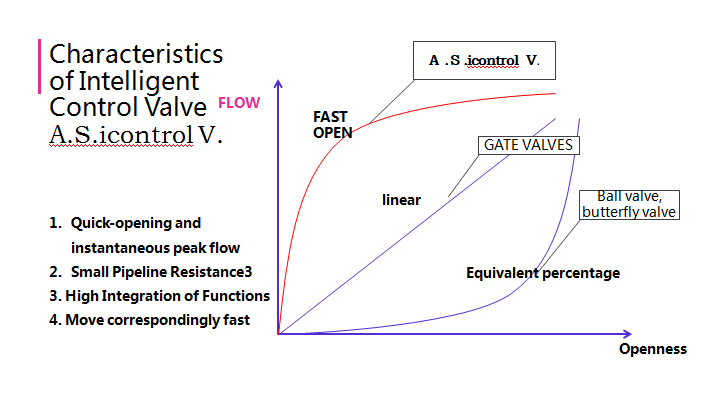

Intelligent control unit (A.S. iControl V) effectively solves the problem of butterfly valve in the use of sprinkler at present. It has excellent open characteristic and can quickly reach the peak value. The flow rate changes little with the increase of opening degree after the peak value. It improves the corresponding speed of control and the reliability and operation convenience of the system. The working system structure of the spraying truck is optimized, and the automation degree of the system is greatly improved. From dehydration of heat conducting oil, heating of asphalt to pipeline cleaning after construction can be completed by a single person in the cab. The degree of automation and intellectualization is much higher than that of the existing market products. The so-called intellectualization of existing domestic products only controls the spraying process, especially the cleaning process often requires cooperation of many people, which is time-consuming, and the working environment is bad.